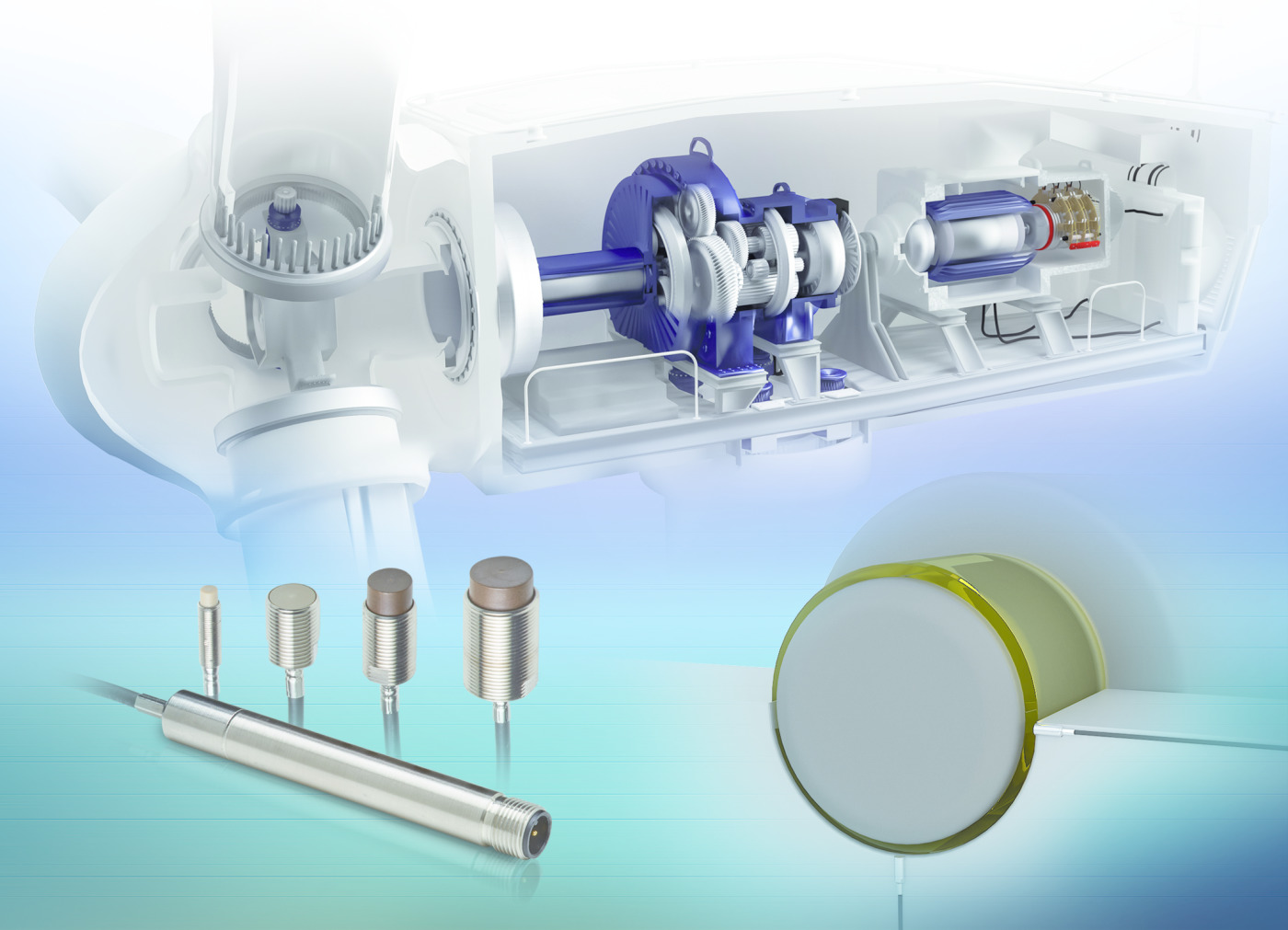

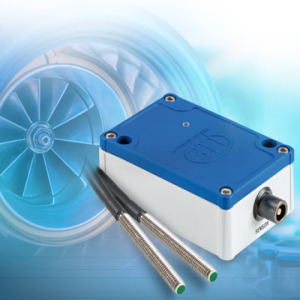

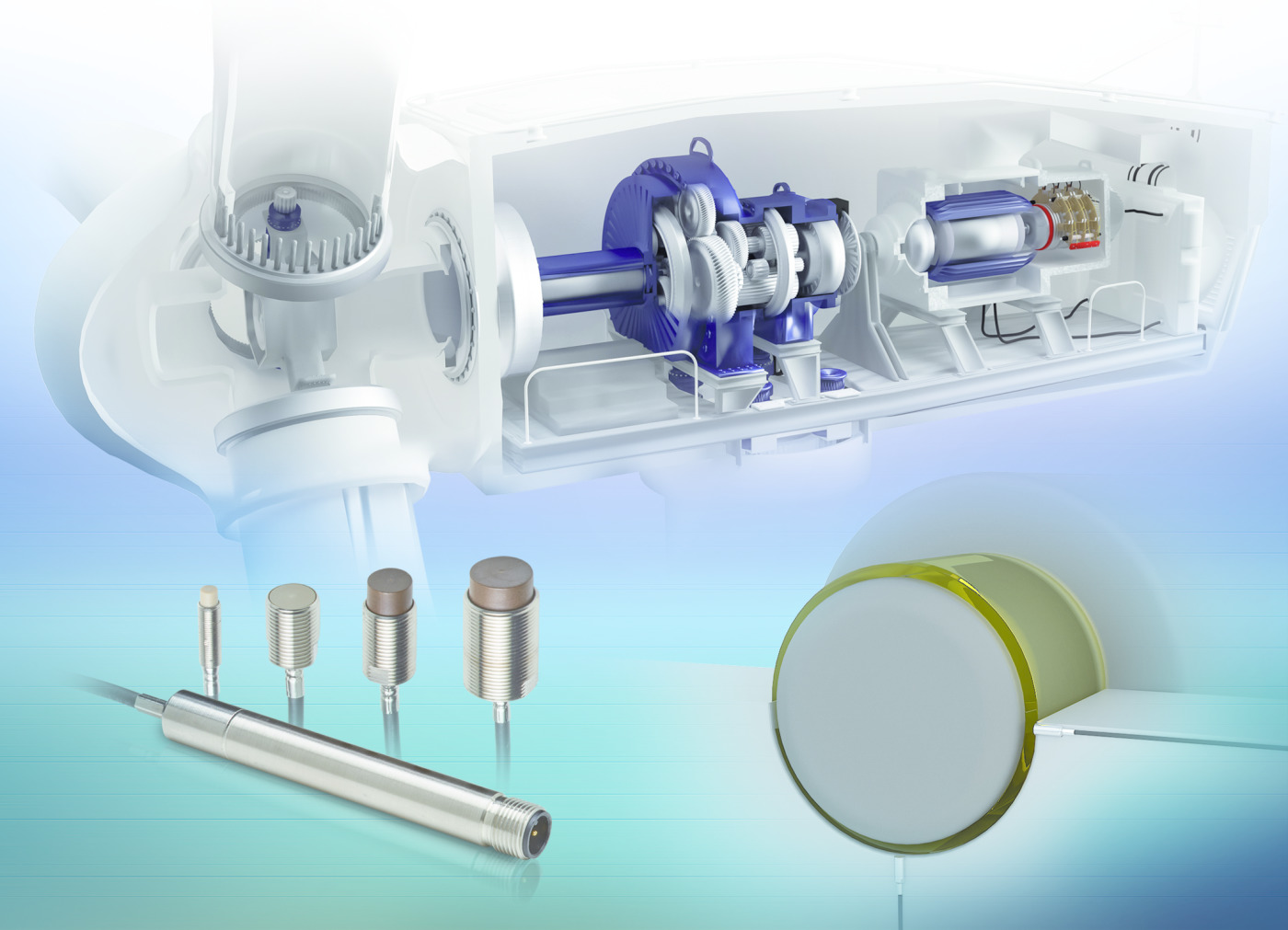

Measuring the bearing gap in wind turbines

In wind

turbines, the bearing gap is very important because the better the sliding

properties, the higher the plant effectiveness and service life. The bearing

gap between the bearing surface and the drive shaft is reliably monitored using

inductive sensors from Micro-Epsilon based on eddy currents.

Wind turbines

typically have two main bearings in which the rotor shaft runs. Due to safety

and cost reasons, wind turbines require 24/7 monitoring. Determining the

bearing gap is one of the most essential tasks in wind turbines, as the bearing

gap provides information about the sliding properties. If the gap width is

reduced, the oil film is also reduced, which should protect the bearing

components from friction-induced wear. In the worst case scenario, reduced

sliding properties cause contact between the components, which causes increased

friction that results in an increase in temperature inside the bearing.

Consequently, the components wear much faster, which could lead to bearing

damage.

To date, bearing gaps

were measured during standstill based on a tactile principle. This meant that

long inspection intervals were required in order to operate the plant for as

long as possible without having to shut it down completely. However, the risk

of a plant failure arose. In contrast,...

+ Read more

To date, bearing gaps

were measured during standstill based on a tactile principle. This meant that

long inspection intervals were required in order to operate the plant for as

long as possible without having to shut it down completely. However, the risk

of a plant failure arose. In contrast, inductive sensors from Micro-Epsilon are

based on eddy currents which enable reliable, fast and cost-effective bearing

gap measurements. It is not necessary to shut down the plant as measurements

are carried out during operation. Since the eddyNCDT 3005 measuring system

withstands oil and bearing-typical oil pressures up to 2 bar, it is ideally

suited to measurement tasks in harsh environments.

The system includes a

sensor with a measuring range up to 6 mm, which is permanently connected to the

controller via a 1 m long cable. It enables the optimization and analysis of

the maintenance intervals. The analog signals are output and can be directly

fed into a PLC. Furthermore, the measured results can be evaluated via external

software. Special features such as linearity calibration and temperature

compensation from Micro-Epsilon enable the sensors to be adapted to suit different

installation positions.

- Read less

Published by Micro-Epsilon USA on Dec 03, 2018

Micro-Epsilon USA

www.micro-epsilon.com

E: [email protected]

T: (919) 787-9707

F: (919) 787-9706

Address

8120 Brownleigh Dr.

Raleigh, NC

27617

United States

View map