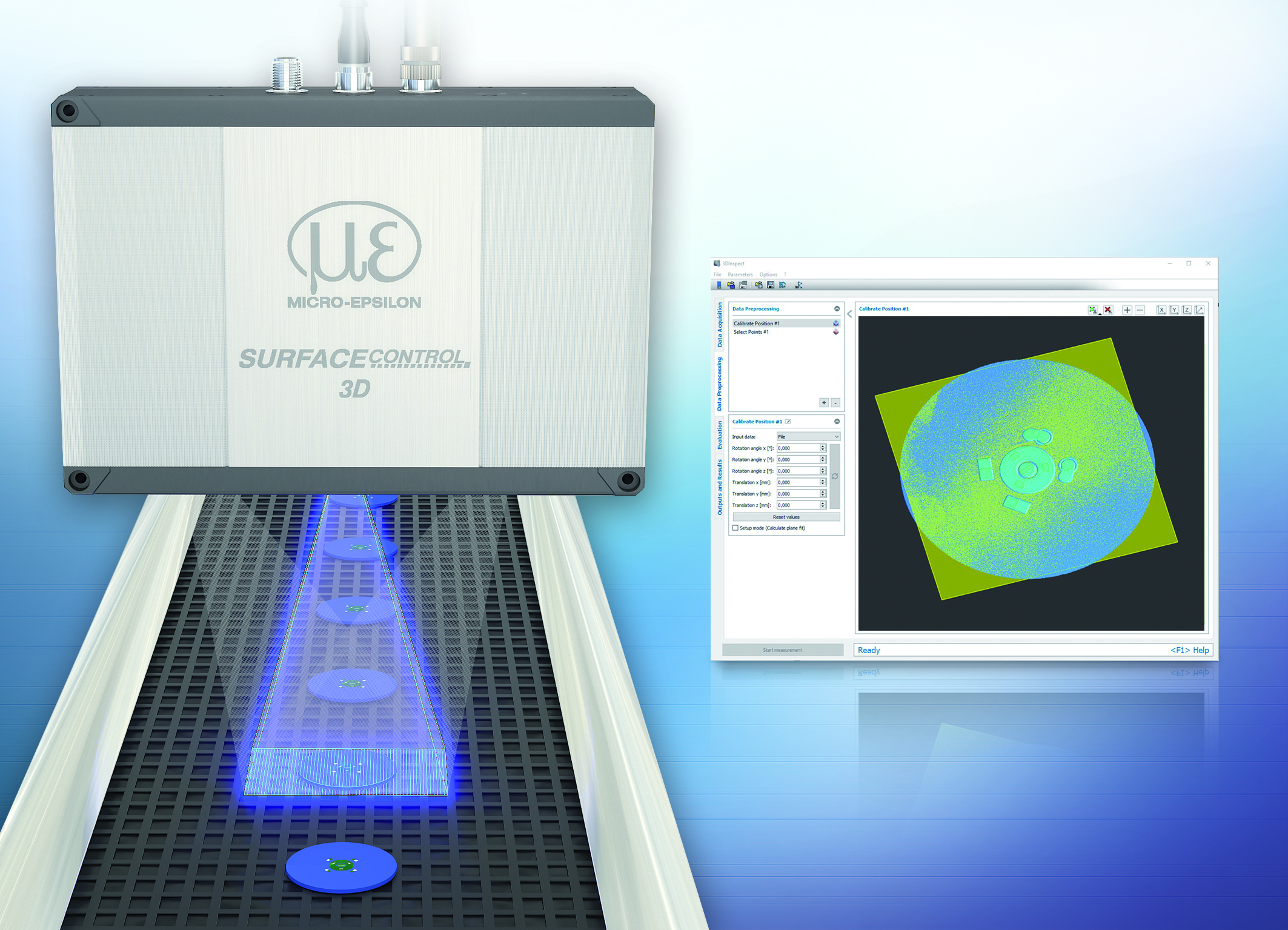

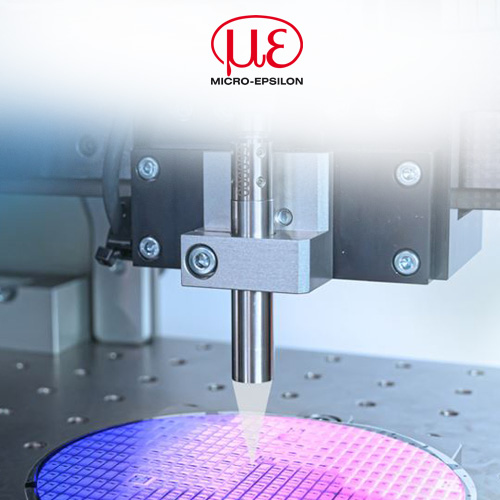

Automated inline 3D measurement for geometry, form and surface inspections

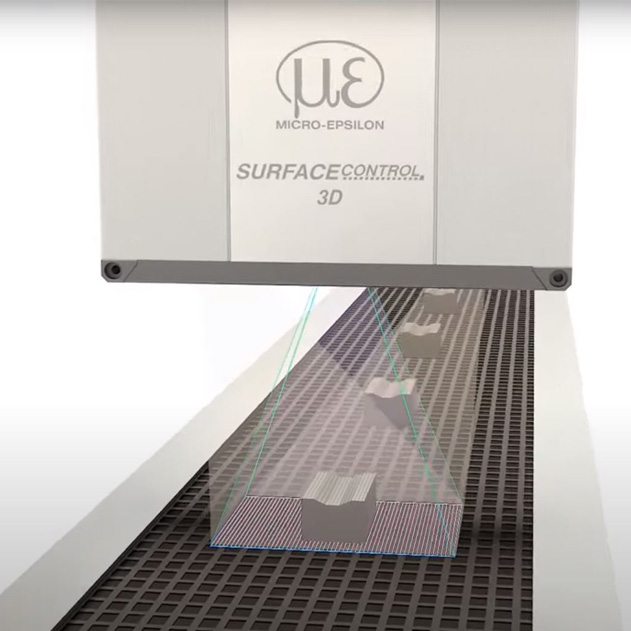

The innovative surfaceCONTROL 3D 3500 sensor from Micro-Epsilon is used for high-precision inline 3D measurements. With a

repeatability of up to 0.4 µm in the z-axis, the sensor reaches a new performance level. The snapshot sensor enables true 3D evaluation of geometry, shapes and surfaces and is used for inline measurements. At the same time, 3DInspect provides an end-to-end software solution for Micro-Epsilon's entire 3D sensor portfolio.

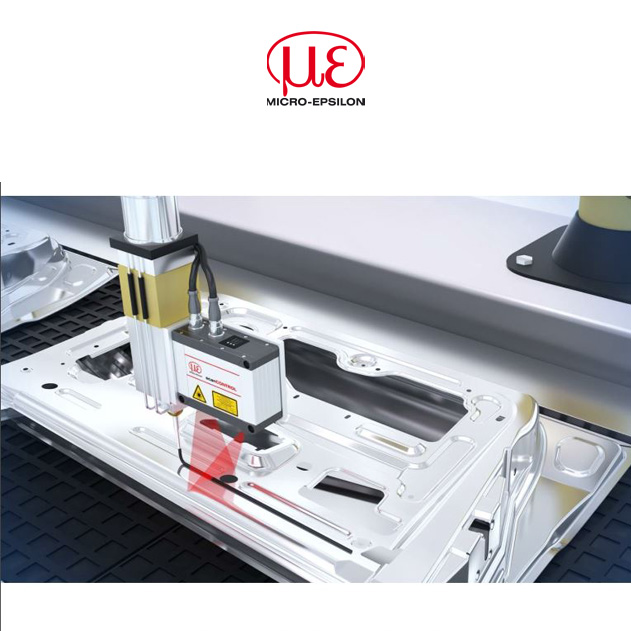

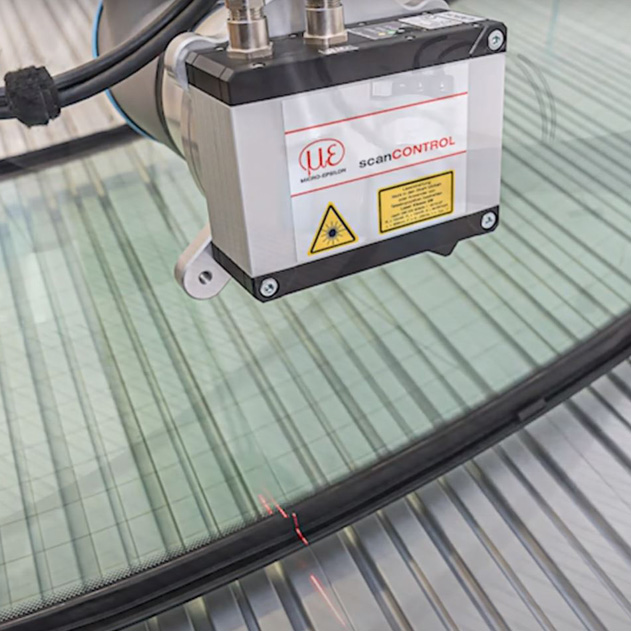

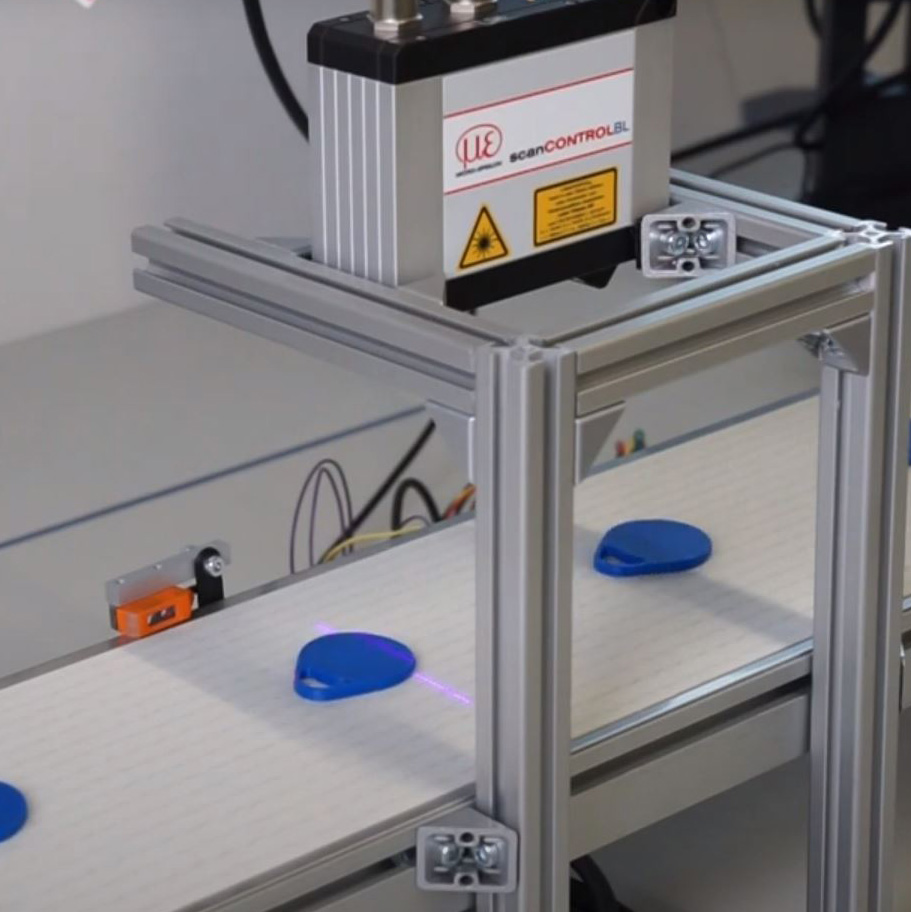

The new surfaceCONTROL 3D 3500 sensor from Micro-Epsilon is designed for high-precision inspection of various surfaces such as metal, plastic or ceramics. In just 0.2 seconds, full-area measurements are achieved via single snapshot for the inspection of

geometry, shape and surface. While conventional systems work with 2.5D, Micro-Epsilon's Valid3D technology enables a full 3D evaluation.

With a z-axis repeatability of up to 0.4 µm, new standards in 3D measurement technology are achieved and the smallest of flatness deviations or height differences are detected reliably. The innovative 3D sensor is used for automated 3D measurement of hole spacing, flatness and coplanarity of prec...

+ Read more

With a z-axis repeatability of up to 0.4 µm, new standards in 3D measurement technology are achieved and the smallest of flatness deviations or height differences are detected reliably. The innovative 3D sensor is used for automated 3D measurement of hole spacing, flatness and coplanarity of precision mechanical parts and electronic components.

The scope of delivery includes the 3DInspect software, which is compatible with all 3D sensors in the Micro-Epsilon portfolio. The modern GenICam standard allows easy integration and high flexibility in the application. The surfaceCONTROL 3D 3500 works

according to the principle of optical triangulation based on fringe projection. Using a matrix projector, a sequence of patterns is projected onto the surface of the measuring object. The light of the patterns diffusely reflected by the test object surface is recorded by two cameras. The three-dimensional surface of the test object is then calculated from the recorded image sequence and the

knowledge of the arrangement of the two cameras to each other.

- Read less

Published by Micro-Epsilon USA on Oct 07, 2021

Micro-Epsilon USA

www.micro-epsilon.com

E: [email protected]

T: (919) 787-9707

F: (919) 787-9706

Address

8120 Brownleigh Dr.

Raleigh, NC

27617

United States

View map