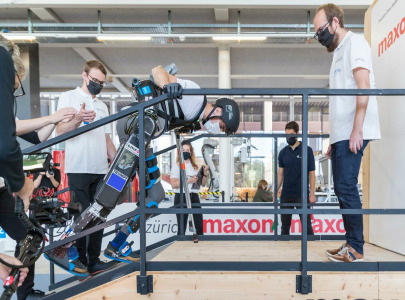

Drive technology and design freedom

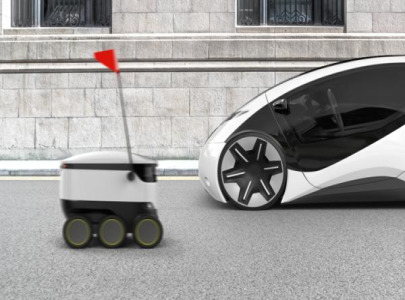

While the development of e-commerce requires the design of compact AGVs, the democratization of autonomous and connected e-mobility vehicles poses safety challenges. In other sectors, it is becoming essential to propose a specific design in order to offer greater ergonomics of use, for example, hand tools, DIY or surgery; and some manufacturers have no other choice than to create attractive designs for customers such as urban users or ever more demanding designers.

While the development of e-commerce requires the design of compact AGVs, the democratization of autonomous and connected e-mobility vehicles poses safety challenges. In other sectors, it is becoming essential to propose a specific design in order to offer greater ergonomics of use, for example, hand tools, DIY or surgery; and some manufacturers have no other choice than to create attractive designs for customers such as urban users or ever more demanding designers.

In this context, companies need to develop motorised solutions, with specific designs. In order to meet the requirements of their end customers, they must be able to rely on a flexible and compact motor, similar to designs by AGV or special machine manufacturers. Aware of these challenges, maxon is developing numerous products designed to facilitate the integration of motorised systems and offer its customers freedom of design.

Freedom of design: how does maxon meet this challenge?

Faced with the new needs met by application engineers, maxon has adapted, finding increasingly better ways of meeting the most specific requests. Discover our range of products and services.

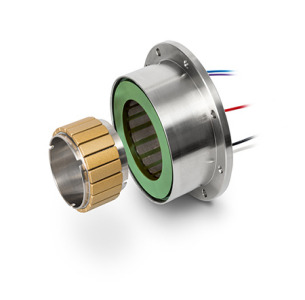

EC Flat motor: ideal for restricted spaces

The brushless EC flat motors are the ideal drive for a large number of applications, thanks to their flat shape. Their simple and well thought through design allows a high level of automation to be achieved in manufacturing, which results in an affordable price. Thanks to an optimized magnetic circuit, the EC-i motors fitted with a ferrous coil have very high power density and reduced reluctance torque. Designed with an internal or external rotor, these BLDC motors can reach a rotational speed of 20,000 rpm.

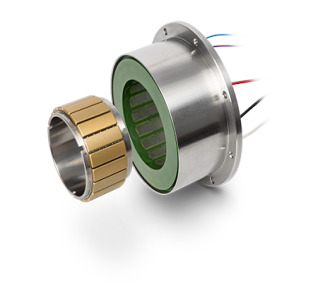

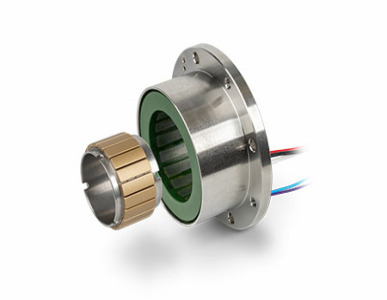

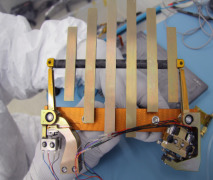

EC frameless flat: for maximum integration

As we know, it is not always possible to fit motors well into an existing structure, such as a robot joint, for example. To overcome this problem, maxon offers its EC flat motors in the form of a frameless motor kit. You thus receive the rotor and the stator separately, without bearings or motor shafts, so that you can choose the best possible combination of high torque density and minimum volume. With external diameters of 45 to 90 mm, they are extremely compact. Their flat design, high torques and generous space for cable passages provide a high level of integration into your application. A tailor-made solution ideal for robotics, in fields as varied as medical, aeronautical or e-mobility.

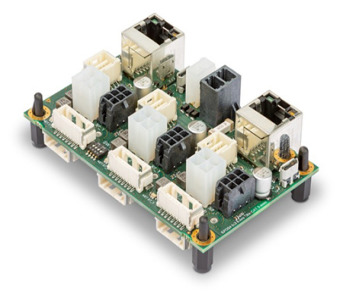

EPOS 4: for simplified positioning

Whether it involves dynamic positioning or precise speed regulation, the maxon EPOS4 is the ideal motor controller for each application. The CANopen interface allows the best possible integration of maxon systems into your field b...

+ Read more

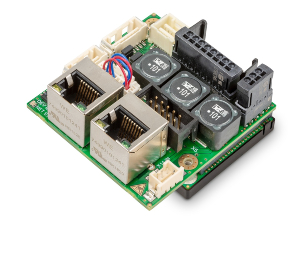

EPOS 4: for simplified positioning

Whether it involves dynamic positioning or precise speed regulation, the maxon EPOS4 is the ideal motor controller for each application. The CANopen interface allows the best possible integration of maxon systems into your field bus architecture. Discover more information here.

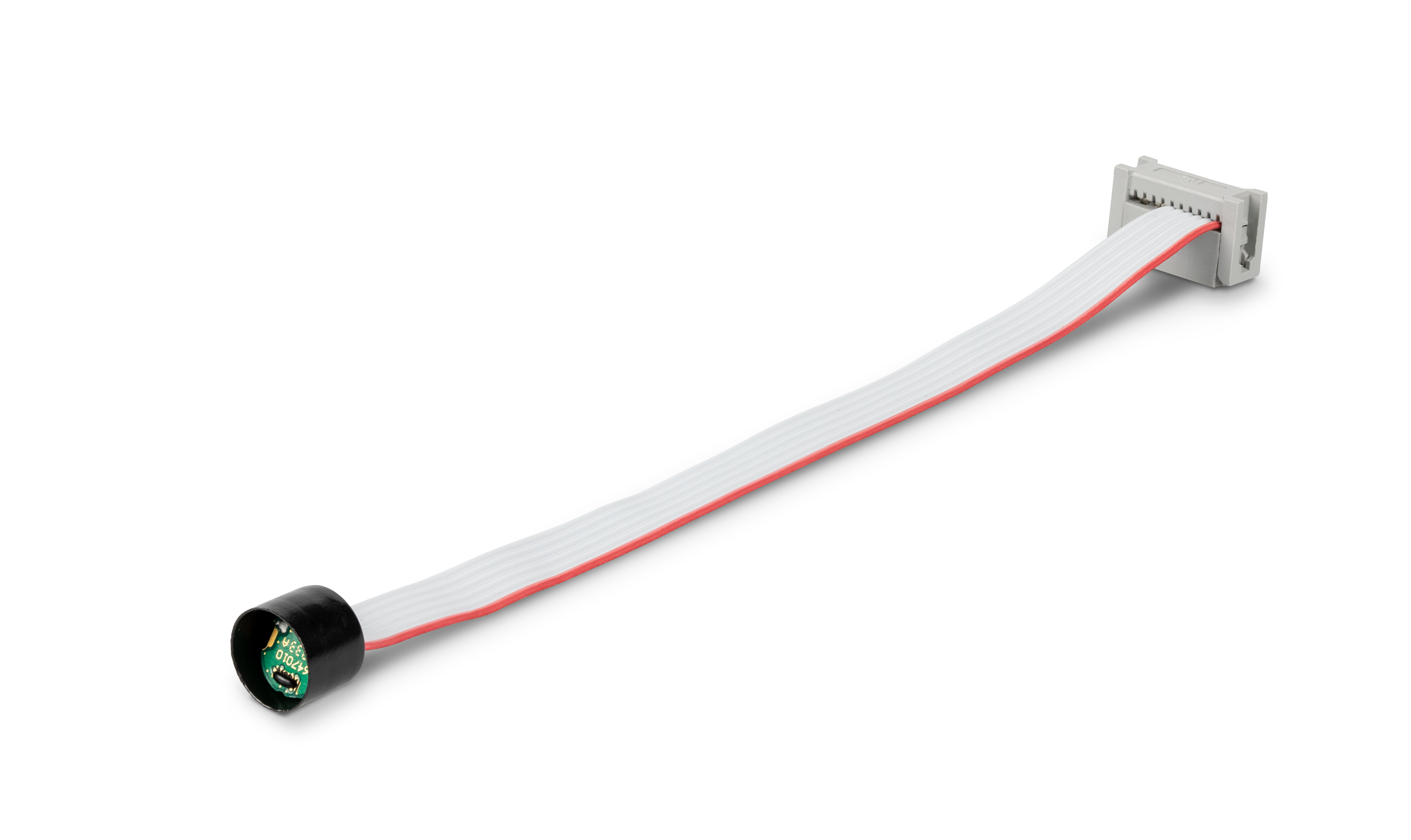

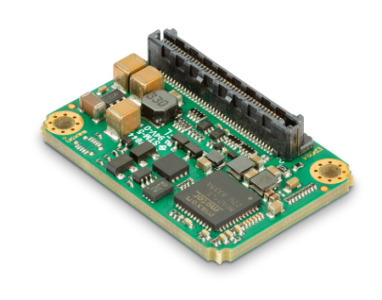

EPOS micro: the EPOS 4 miniature version

A new miniaturized controller, the EPOS4 Micro 24/5 CAN benefits from a size of only 32 mm x 22 mm. The attractive price/performance ratio, with practically identical functions to those of the other models in the range, responds to single and multi-axis cost-sensitive applications.

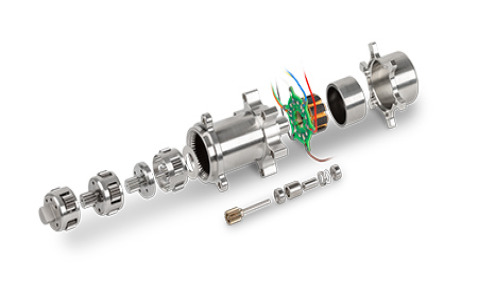

DCX: compactness and high power density

The DCX motors are impressive because of their high power density (speed and torque available within the product volume) and their perfectly silent operation. Thanks to their robust design patented worldwide, these brushed DC motors offer a highly dynamic drive, in practically all situations. High-performance DCX motors, available with gears and encoders, can be configured online and are delivered within 11 working days.

DCX 10S: perfect for prostheses

More specific, the DCX 10S is used for its performances with prostheses. The DCX 10 S is available as a small pre-stressed ball bearing or sintered bearing drive. The spark removal function (CLL), available as an option, provides exceptional longevity to this DC motor fitted with precious metal brushes. The compact DCX drive systems are used in particular for hand and foot prostheses. They are distinguished by their high power density (torque per volume) and their completely silent and fluid operation.

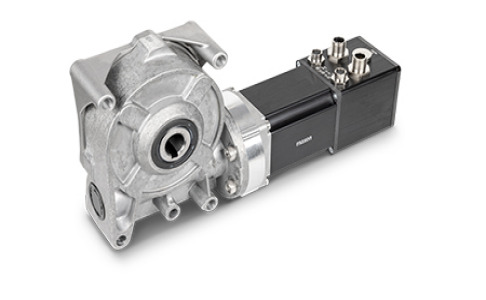

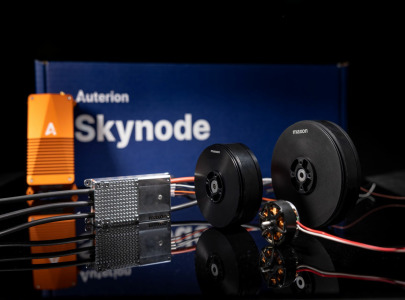

IDX: 20% more compact than its competitors

A new compact range of motors, the IDX has been designed to meet industrial, intelligent and compact motor needs. For space savings, it is possible to have the IDX without integrated electronics (using a remote EPOS4 board), but still with the IP65 protection around the motor. This arrangement optimizes the integration of the motor and its controller.

What functions should a motor controller have? What means are used to control movement? Where should the controller be placed? As part of the design of an AGV, such as a logistics shuttle, the development engineer must take several aspects into account. Consequently, maxon offers as many options as possible to allow you to choose the best option possible for your application. Thus, it is possible to choose between an integrated positioning and speed controller, or for example, placing the controller on the outside, and therefore not in the motor. In addition, maxon provides all regulators with the CANopen or EtherCAT communications bus system. If no master system is used, maxon also suggests controlling the variable speed drives with analogue or digital I/Os.

It should be noted that the new IDX motor range can also be configured online.

Motorized wheel: compact solution for more mobility

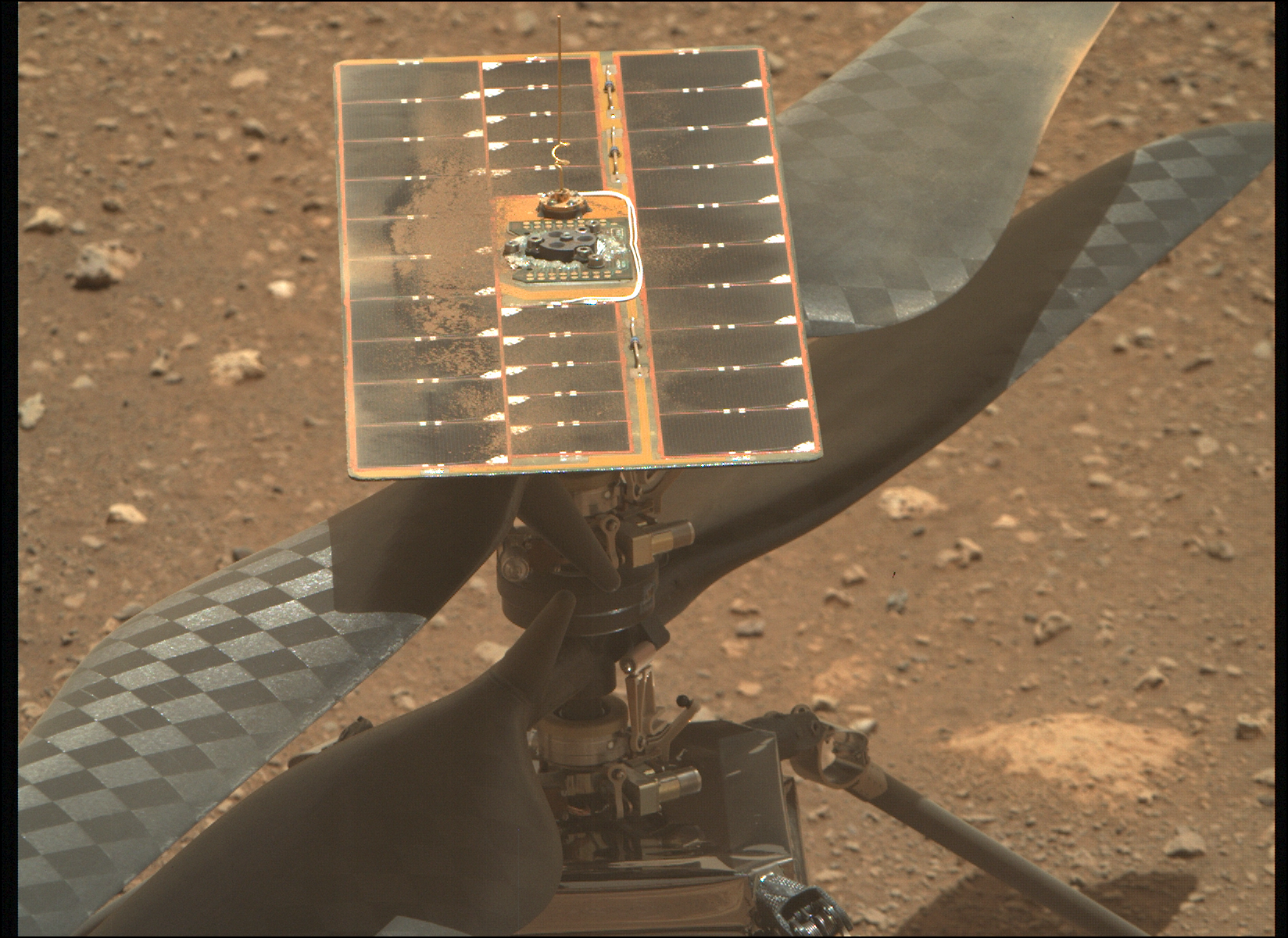

The maxon motorized wheel is a compact solution for AGVs and autonomous vehicles for intralogistics and outdoor applications.

Introduced at SPS 2019, this maxon innovation offers high performance, compactness and reliability. Ask our teams for a demonstration to configure your project.

Battery systems: more mobility with modular dimensions

From prototype to production, maxon ensures mobility regardless of the application - from autonomous robot to portable device, including electric sport e-scooters. With the maxon Battery Management System (BMS), the battery blocks developed by us are perfectly adapted to the driving systems described in this article.

Optimized mechatronics solution: adaptation of standard products

Based on standard components, this optimized solution will help your appliance to travel efficiently at the best possible cost. Motor, brake, gear, electronics, wiring, etc. We can meet your needs very quickly, from the simple adapted standard (Flex) to more specific products: the design of multi-axial, autonomous and intelligent mechatronics systems. Contact our teams.

maxon, mechatronics partner of applications with freedom of design

In conclusion, thanks to its unmatched winding techniques offering compactness, power torque and energy efficiency, maxon has a wide range of compact and modular motors. In order to meet these integration challenges – essential for many robotics, e-mobility or industrial automation applications, the EC Flat and IDX ranges specially designed to adapt to these compactness needs will be widely acclaimed.

More specifically, the IDX range with and without electronics is a response for the development of special compact machines, as well as for the development of powerful and compact logistics AGVs.

Want to learn more about IDX?

Find out more: contact our teams for more information and further help in developing your projects using maxon.

Visit idx.maxongroup.com

- Read less

Published by maxon on Sep 22, 2020