5 challenges an electric motor has to overcome on Mars

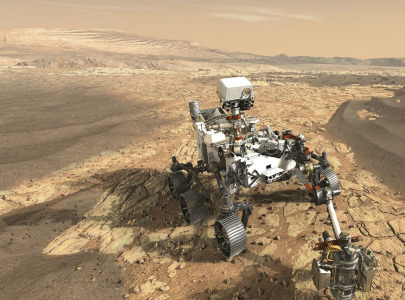

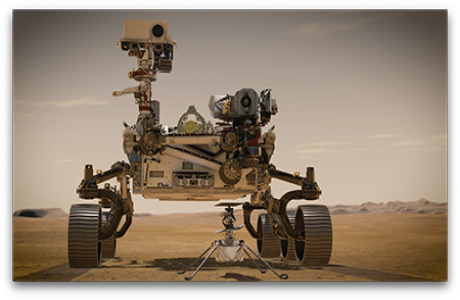

Outer space is unforgiving. This is why precision drives

embarking on a trip to other planets need to meet extremely high-quality

standards.

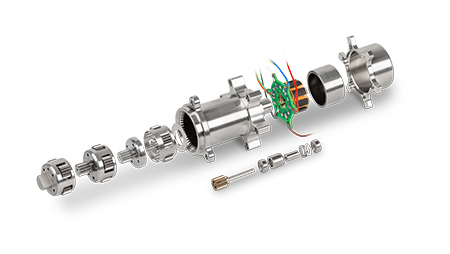

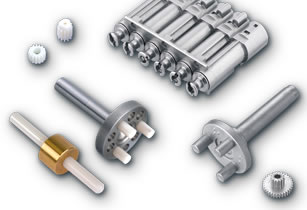

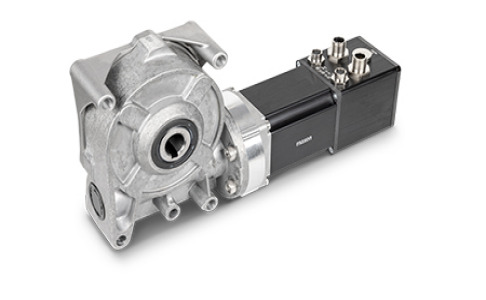

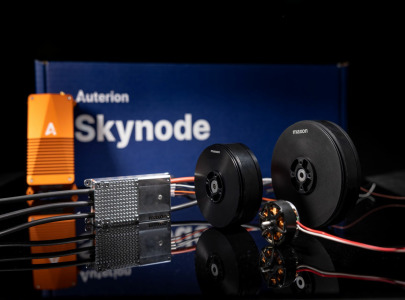

Every Mars drive from maxon is based on a catalog product

and is modified for the specific mission. That’s because the DC motors,

gearheads, and encoders face brutal conditions during liftoff, the long journey

through space, and the mission on the Red Planet. In this blog, I will talk

about the properties a drive needs to have to qualify for a journey to Mars.

Outer space is unforgiving. This is why precision drives

embarking on a trip to other planets need to meet extremely high-quality

standards.

Every Mars drive from maxon is based on a catalog product

and is modified for the specific mission. That’s because the DC motors,

gearheads, and encoders face brutal conditions during liftoff, the long journey

through space, and the mission on the Red Planet. In this blog, I will talk

about the properties a drive needs to have to qualify for a journey to Mars.

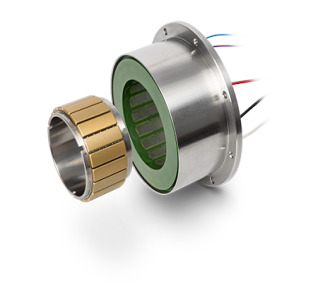

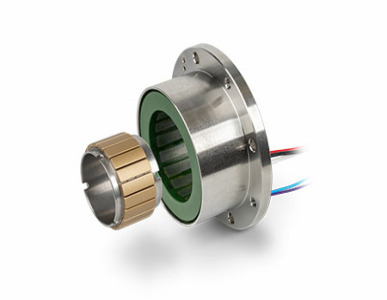

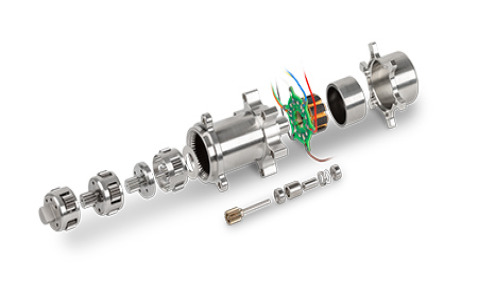

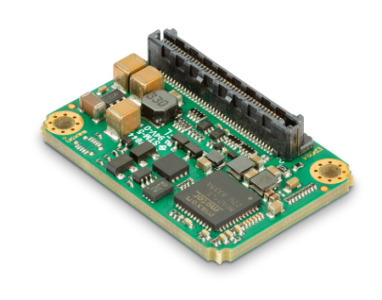

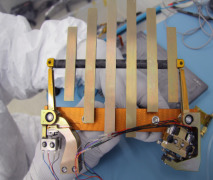

Vibration and shock

The first challenge is to survive the rocket launch. This

means that the motor must be resistant to shock and vibration. The vibration is

not as strong as people might think: A little more than on a passenger plane,

but not much more, and only for a few minutes. Shocks, on the other hand, are

something that we need to deal with on a regular basis when working with

standard products. These occur mainly during staging, which is when the first

stage separates from the rest of the rocket. The resulting forces would destroy

normal motors because the rotor would become separated from the stator. That’s

why we need to reinforce our drives, for example by encapsulating the rotor and

using special welds, special retaining rings, and optimized materials.

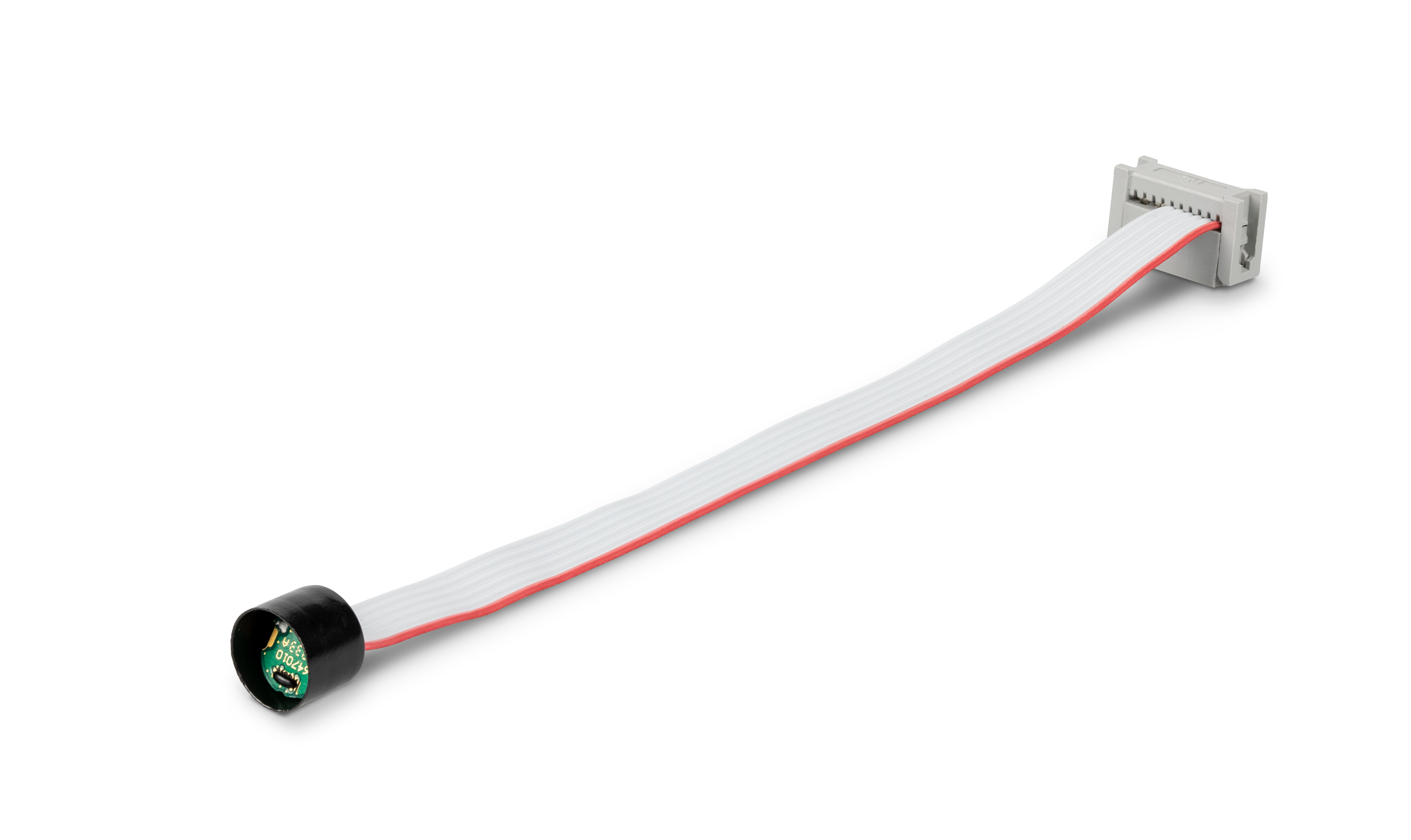

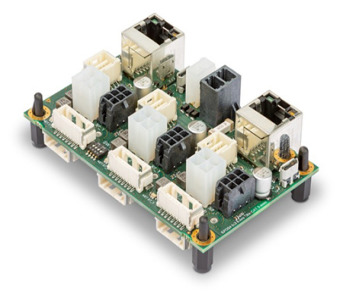

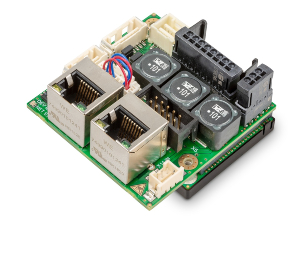

Vacuum and radiation

The trip to Mars takes about six months. During this time,

the drives need to survive the vacuum and radiation. The most damaging

radiation doesn’t come from the Sun, but from high-energy particles from

outside the solar system, which can damage the electronics. That’s why we need

specially hardened electronics for the Hall sensors on the motors. To be extra

safe, we’re installing them in pairs for redundancy. In a vacuum, the

durability of components is important. You can’t use a glue that undergoes

changes in its chemical properties and loses its adhesiveness after a few days

in a vacuum.

Published by maxon on Nov 11, 2020