NREL Projects Leverage VABS Software for Complex Wind Turbine Rotor Blade Simulation

Project explores advantages of large-scale rotors with innovative, highly flexible blades

West Lafayette, Indiana (USA) - AnalySwift, LLC, a provider of efficient high-fidelity modeling software for composites and other advanced materials, announced today the U.S. Department of Energy’s National Renewable Energy Laboratory (NREL) is using its VABS blade simulation tool in two recent projects. The software is used to generate accurate blade properties, a key piece in the overall success of renewable energy projects.

From a distance, the typical observer may have little appreciation for the complexity that comprises a modern wind turbine blade. Such blades can be more than 100 meters long, with dozens of separate layers of advanced composite materials. Increased complexity, however, does not come without its challenges. For instance, representing these blades in a computer model would require billions of degrees of freedom to accurately capture all the engineering properties, overwhelming available computing resources.

Realizing similar challenges in the aerospace industry 30 years ago, the US Army began funding development of a software technology called VABS to model composite helicopter rotor blades. The software matured over time to compute all the properties of composite rotor blades efficiently and accurately by modeling the very complex blades using simple engineering beam theories. Using VABS, engineers gained the ability to confidently evaluate the performance of existing composite blades, as well as design blades for desired behavior, naturally setting the stage to move beyond aerospace to tackle problems in other industries, including renewable energy.

NREL’s focus is on creative answers to today's energy challenges. Equipped with AnalySwift’s VABS software in its workflow, NREL research will be supported with accurate modeling of the engineering properties of even the most complex wind turbine blades. Use of VABS within NREL is currently supported by two projects, namely, the Atmosphere to Electron High-fidelity Modeling (HFM) project, as well as the Big Adaptive Rotor (BAR) project.

Atmosphere to Electron High-fidelity Modeling (HFM) Project

NREL’s HFM project aims to use high-performance computing to understand and accurately model fundamental physics on appropriate temporal and spatial scales to predict complex, rapidly changing inflow to the win...

+ Read more

Atmosphere to Electron High-fidelity Modeling (HFM) Project

NREL’s HFM project aims to use high-performance computing to understand and accurately model fundamental physics on appropriate temporal and spatial scales to predict complex, rapidly changing inflow to the wind plant, complex flow within a wind plant, and the response of individual turbines and the wind plant as a whole to the flows.

Big Adaptive Rotor (BAR) Project

The BAR project’s goal is to maximize the advantages of large-scale rotors and their potential for increased energy generation through innovative design of highly flexible blades.

Enter VABS

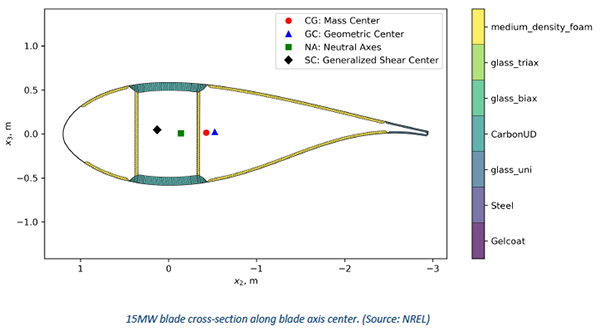

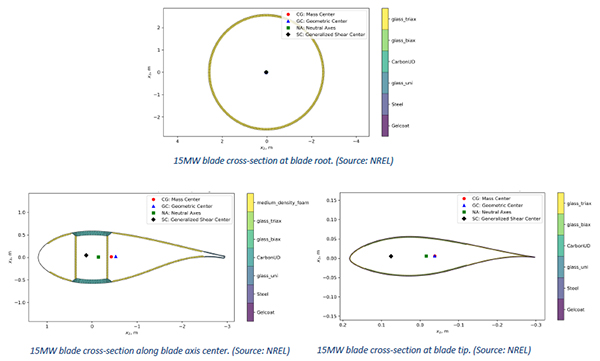

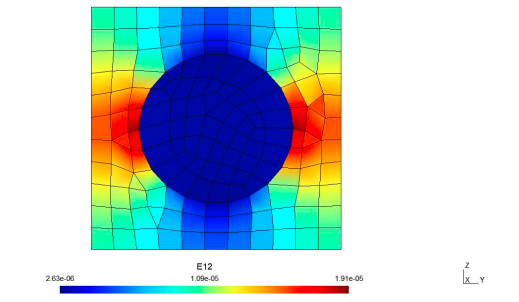

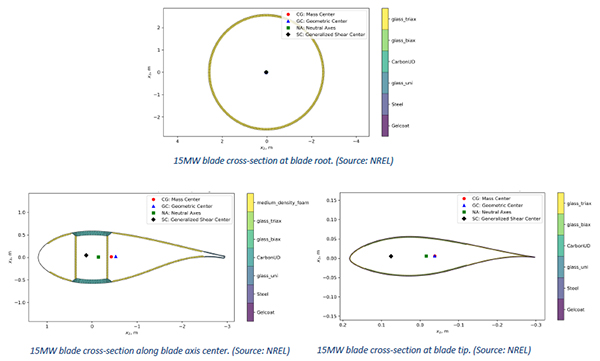

The VABS software program has helped researchers at NREL generate cross-sectional stiffness and mass properties for modern wind-turbine blades with pre-bend and twist designed and used in the aforementioned projects. The properties computed via VABS are used as inputs by BeamDyn, a nonlinear finite-element beam model based on the geometrically exact beam theory (GEBT). BeamDyn is NREL’s blade modeling tool of choice for turbine simulations coupled with high-fidelity computational fluid dynamics.

Recent efforts at NREL have focused on validation of BeamDyn for long, flexible blades (both curved and straight) with bend-twist coupling by comparing quantities of interest such as blade displacement and rotations against resolved nonlinear shell finite-element models.

According to NREL, one of the use cases considered for validation is that of the 15-megawatt offshore reference wind turbine design. Based on the composite layup definition of the blade, researchers at NREL used VABS to compute the blade beam stiffness and mass properties for cross sections along the blade axis. 15MW blade cross-section at blade root. (Source: NREL)

About VABS

VABS is a general-purpose cross-sectional analysis tool for predicting structural properties and recovering 3D stresses/strains of slender composite structures, including helicopter, eVTOL/UAM, and wind turbine rotor blades, propellers, landing gear, wing sections, golf clubs, beams, poles, columns, tubes, and many more. VABS provides the best composite beam theory, which can handle arbitrary sections and calculates the most accurate beam properties and layerwise 3D stresses/strains.

About AnalySwift

AnalySwift, LLC is a provider of simulation software for composites, which enables an unprecedented combination of efficiency and accuracy, including multiphysics structural analysis and micromechanics modeling. Drawing on cutting edge university technology, AnalySwift’s powerful solutions provide customers a competitive advantage through drastic reductions in engineering time, virtual testing earlier in the design process, and handling of more 15MW blade cross-section along blade axis center. (Source: NREL) 15MW blade cross-section at blade tip. (Source: NREL) complex composite structures. The company’s technologies deliver the accuracy of detailed 3D FEA at the efficiency of simple engineering models, cutting analysis time by orders of magnitude. SwiftComp is licensed from Purdue Research Foundation. VABS is licensed from Utah State University, Georgia Institute of Technology, and Purdue University. Find out more at analyswift.com.

Media Contact:

Allan Wood

(801)-599-5879

[email protected]

www.analyswift.com

###

- Read less

Published by AnalySwift, LLC on May 13, 2021

AnalySwift, LLC

T: (801) 599-5879

Address

1780 North Research Park Way

Suite 108

North Logan, UT

84341

United States

View map