MicroE Systems Partners with OEMs to Solve Tough Design Challenges in Robotics Applications

Designers of robotic systems face many difficult challenges and constraints. Minimizing the size and weight of motion control components is often necessary to meet system design requirements. Integrating adjacent components into an optimized assembly is increasingly required to meet performance and cost targets. Robots and humans are interacting on an unprecedented scale, making reliability more critical than ever before.

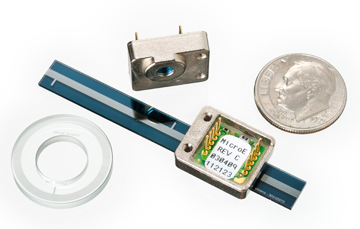

MicroE Systems has been designing miniature encoder products and working closely with OEMs to engineer highly optimized motion control solutions in the most demanding applications for over 20 years. MicroE’s wide range of miniature optical encoders, depth of application expertise and proven reliability has recently enabled two leading robotics OEMs to achieve their design goals with their next generation robotic systems.

High density, multi-axis medical robot

A customer designing a medical robot needed to install multiple axes in an extremely small space near the end of their robot arm. There was no off-the-shelf solution available to meet their demanding performance, size and weight requirements. MicroE’s engineers teamed up with the customer to deliver an ultra-compact multi-axes encoder system that allowed them to accomplish their design goals.

Published by Celera Motion on Apr 01, 2014