SPIROL Publishes Updated Alignment Dowels/Bushings Catalog

SPIROL recently published their updated Alignment Dowels and Bushings catalog.

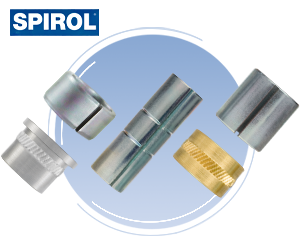

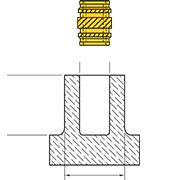

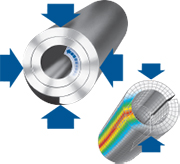

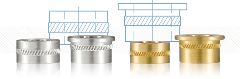

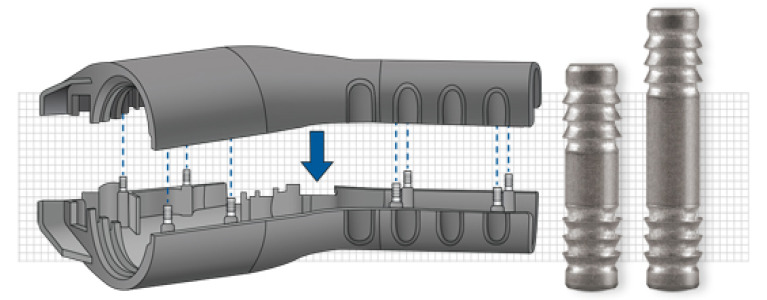

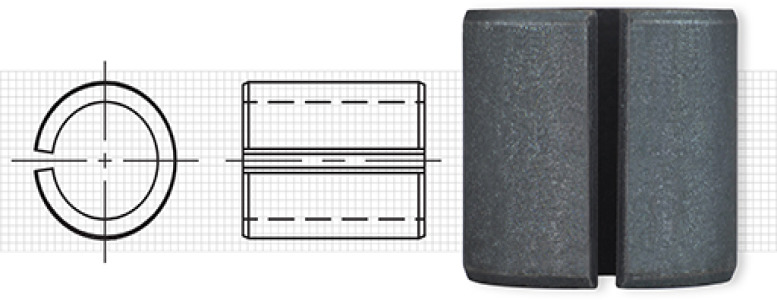

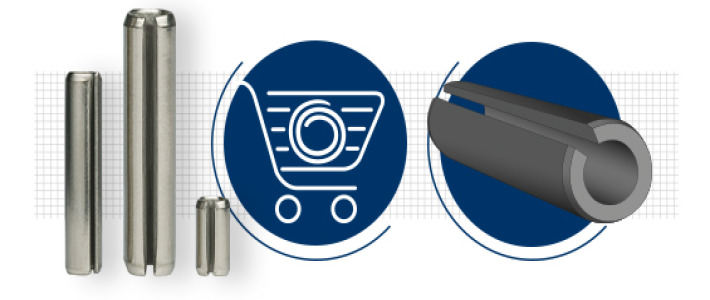

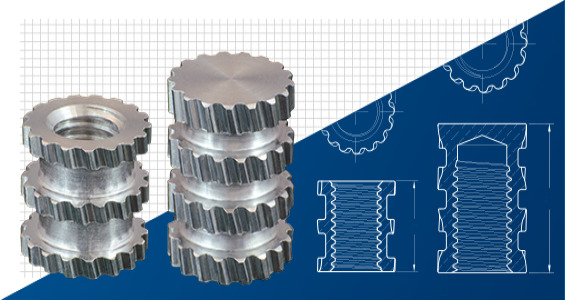

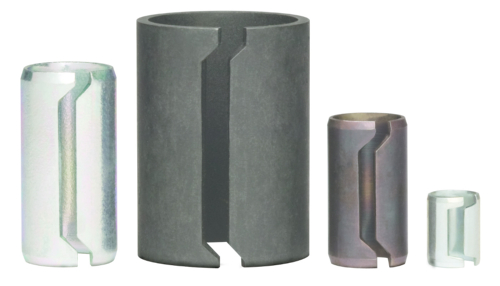

SPIROL recently published their updated Alignment Dowels and Bushings catalog. Used primarily for positioning and alignment, these roll formed, hardened components significantly reduce costs as compared to traditional hardened Solid Dowels by eliminating the need for precision tolerances and the drilling of a separate bolt hole for locating.

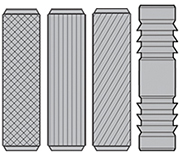

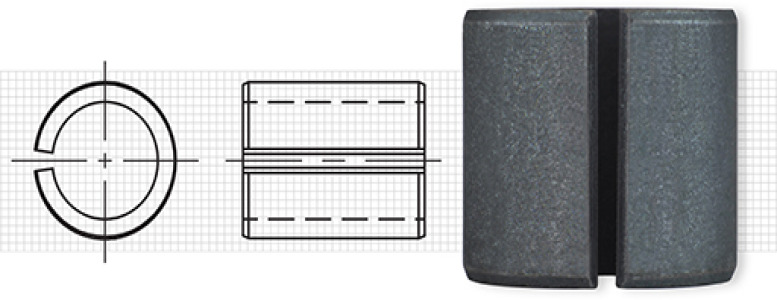

Both DB100 Dowel Bushings and SD200 Spring Dowels are manufactured from high carbon steel, and heat treated for strength and flexibility. The staggered split seam design enables the absorption of wide hole tolerances while preventing interlocking of the components.

Published by SPIROL International Corporation on May 08, 2018

SPIROL Canada

3103 St. Etienne Blvd.

Windsor, Ontario

N8W 5B1

Canada

T +1 (1) 519.974.3334

F +1 (1) 519.974.6550

E [email protected]

SPIROL China

1st Floor, Building 22, Plot D9, District D, No. 122 HeDan Road, Wai Gao Qiao Free Trade Zone

Shanghai

200131

China

T +86 (0) 21 5046-1451

F +86 (0) 21 5046-1540

E [email protected]

SPIROL Mexico

Avenida Avante #250, Parque Industrial Avante Apodaca

Apodaca

Nuevo León

66607

Mexico

T +52 (01) 81 8385 4390

F +52 (01) 81 8385 4391

E [email protected]

SPIROL United Kingdom

17 Princewood Road

Corby

Northants

NN17 4ET

United Kingdom

T +44 (0) 1536 444800

F +44 (0) 1536 203415

E [email protected]

SPRIOL Brazil

Rua Mafalda Barnabé Soliane, 134 - Comercial Vitória Martini, Distrito Industrial

Indaiatuba

São Paulo

CEP 13347-610

Brazil

T +55 19 3936 2701

F +55 19 3936 7121

E [email protected]

Visit www.SPIROL.com for a complete list of all locations:

https://www.SPIROL.com/global-locations/