Laser plastic welding with scanner & DOE

In laser welding of plastics a scanner is usually used for quasi-simultaneous welding. A diffractive optical element, called DOE is in general used for beam shaping in simultaneous welding method. So, why should a scanner and a DOE be used together? – for beam shaping in quasi-simultaneous or contour welding.

The laser beam can be shaped with the use of a DOE. By applications with a scanner and a diode laser the larger beam diameter can be generated without changing working distance or F-theta lens. The DOE just needs to be positioned in the collimated beam at the entrance of the scanner.

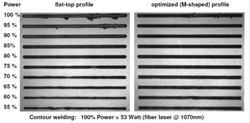

Working with fiber lasers even small beam diameters with special characteristics can be formed due to better beam quality. The DOE splits the beam in plurality beams with new orientation and weighing. Thus the laser power distribution can be shaped to an optimized energy or heat input in the welding zone. First welding tests with a DOE forming an M-shape showed welding s with a larger process window. The welding seam is more constant in width and showed less visual errors even by different energy inputs.

Published by Leister Technologies Process Heat on Apr 15, 2015